How to conduct an incident investigation

In Europe, every year over 40 million working days are lost through work-related injuries and ill health, at a cost to business of £2.5 billion. (1)

It’s particularly distressing when an injury happens more than once at the same company, indicating that lessons aren’t being learnt. Responding to accidents is at the heart of preventing them from repeating, so it’s crucial to identify what went wrong and take reformative steps – this is the core principle of an incident investigation.

What is an incident investigation?

Incident investigation is a process for reporting, tracking, and implementing change in response to workplace accidents.

An effective investigation requires a methodical, structured approach which begins with information gathering on equipment, procedures and the event in question. Input is expected from a number of stakeholders, not only the ones present when the incident occurred. Once there’s sufficient information, analysis of the failings which led to the incident can take place. The findings will form the basis of an action plan to prevent the accident from happening again and for improving your overall management of risk.

Which events should be investigated?

Not all incidents merit a full incident investigation – the decision it partly down to the HSE managers judgement. Weight should be given to the consequences (or potential consequences) of the incident and the likelihood of it happening again.

Who should carry out the investigation?

For an investigation to be worthwhile, it is essential that the management and the workforce are fully involved. Depending on the level of the investigation (and the size of the business), supervisors, line managers, health and safety professionals, union safety representatives, employee representatives and senior management/ directors may all be involved. As well as being a legal duty, it has been found that where there is full cooperation and consultation with union representatives and employees, the number of accidents is half that of workplaces where there is no such employee involvement.

How most companies do it in practice?

When investigating an incident, companies usually use a pen and paper during data collection to make note of all relevant details, this information is then typically analysed using post-it notes in an office to drill down to the root cause of an incident. The 5 why method will often be used with a heavy focus on the materials and process side of things. Unfortunately, in these cases there is often only a nod towards the Human Factors causal factors, which means key factors that lead to the incident may be missed, not addressed and lead to a recurrence of the incident.

Frequently, those conducting the analysis of the incident are not fully acquainted with the full range of human factors elements which may have contributed to the incident, and in some cases are not from the company itself but from external organisations sometimes based a distance away from the company where the incident occurred.

The problem with these approaches is that aspects of the incident may be missed in the post-it note investigation, and these notes will require electronic capture once the investigation has been complete. This adds to the workload of those carrying out the investigation and increases the possibility of information being lost due to lost or miss placed post-it notes. Although steps may be taken to ensure a systematic analysis of the different aspects of the incident, parts of the process may be missed or not analysed as deeply as they could be as there is a reliance on memory of what should be reviewed when it comes to assessing the contributing human factors elements. Where external individuals have been brought in to conduct the investigation and analysis, they may lack the local knowledge and insight required to fully understand what went wrong.

Why HF-AIR offers the best approach

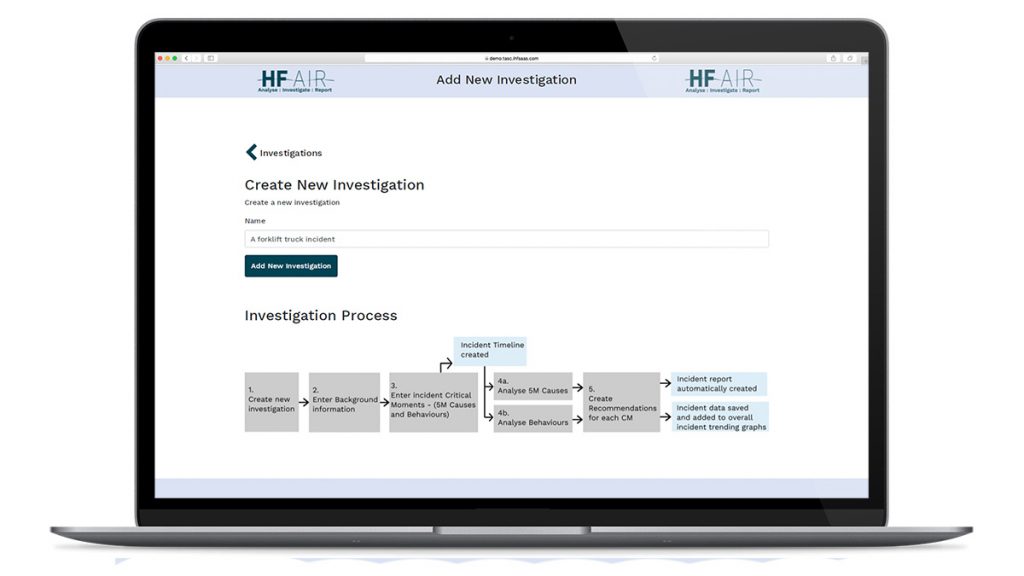

HF-AIR™ is a complete online incident investigation system. The integrated analysis tools allows you to investigate technical failures and human errors then save your reports all in one place.

The tool is designed to provide you with an online application that enables the easy input of the timeline of an incident, which includes in depth cognitive behaviour and 5-M (Machinery, Methods, Materials, Mother nature and measurement) causal analysis. These analysis tools allow you to focus on each critical step of the incident, drill down to the contributing factors, including those associated with the individual and the organisation, and develop a clear understanding of why the incident occurred. This makes it easier to identify recommendations for improvement to ensure that the incident, or one like it, does not occur again.

Once the analysis has been completed and recommendations have been identified, this information can be easily downloaded within the format of a report that captures all of the information provided in a well laid out, easy to read word format. This structure can be tailored to your organisation to ensure that it fits your reporting structure and styling. Furthermore, the intention with this software is to train your employees to use it, this provides them with ownership and a developed understanding of what leads to and may cause an incident.

Our software also provides you with the ability to conduct a top-level analysis of all of the investigations conducted within your company. It provides you with the opportunity to identify across the different incident types what proportion of critical moment types have occurred, and the type of cognitive and 5M causes have been more likely to occur. Furthermore, our tool provides a central space for all documents including incident records and interview notes. This enables easy access of information for reference and auditing purposes at a later date and ensures that no information is lost with staff changes.

If you’re interested in a demo of HF-AIR then please get in touch

References

1 European Social Statistics: Labour Force Survey Results 2001 ISBN 9289436050