Comprehensive and focused incident investigation software designed using best practices from human factors experts.

Go beyond surface-level human error identification and root cause box ticking while meeting regulatory compliance with the added value of achieving long-term financial savings.

Request a DemonstrationAre You Still Using Paper, Spreadsheets and Word Processor Documents to Manage the Safety-Critical Accident and Incident Investigation Process?

In safety-critical industrial operations, accident and incident investigations managed using paper, spreadsheets and word documents can lead to problems such as auditability, control, incompleteness and reportability to regulators. This grows in complexity when organisations operate multiple sites without consistent and repeatable processes, intelligent trending and visibility of accidents/incidents. According to the COMAH Competent Authority, learning from incidents and accidents is important to ensure organisations prevent future similar incidents. After an accident/incident involving human failure, the investigation into the causes and contributing factors often makes little attempt to understand why the human failures occurred. Determining both the immediate and the underlying cause of an accident/incident is the key to preventing similar occurrences through the design of effective control measures and organisational learning.

Problematic Paper, Spreadsheets and Word Processor Documents

The utilisation of traditional accident and incident investigation management tools can lead to difficulties that may result in data gaps. Such as auditability and repeatability, disparate, duplicated and scattered documents, incomplete and inconsistent processes, lack of control and visibility, potential data loss, reportability to regulators and the time wasted due to rework.

Human Factors in Accident and Incident Investigations

Guidance and regulations exist from different nations and sectors that state organisations need to conduct accident and incident investigations with human factors considerations. For example, WorkSafe Western Australia state that the investigation of human factors should be an integral part of any high-potential near miss, Major Accident Event (MAE) or Major Incident (MI) investigation. In the UK, related guidance includes “Reducing error and influencing behaviour (HSG48)” from the Health and Safety Executive (HSE), “Rail Industry Standard for Accident and Incident Investigation (RIS-3119-TOM)” from the Rail Safety and Standards Board (RSSB), “Human reliability (EHF.10)” from the Office for Nuclear Regulation (ONR) and “Human Factors Engineering in the Design of Nuclear Power Plants (SSG-51)” from the International Atomic Energy Agency (IAEA).

COMAH Establishment Requirement

Topic 1 of the COMAH Competent Authority: Inspecting Human Factors at COMAH Establishments Delivery Guide relates to “Managing Human Performance” and Human Factors Specialist Inspectors are likely to inspect and rate this topic first, making the efficient implementation and practice of accident and incident investigation an integral part of the general duty under COMAH and and The Control of Major Accident Hazards Regulations 2015, Section 5. Paragraph 432 of the L111 Guidance on Regulations states: “Reactive monitoring requires an effective system for reporting incidents and accidents and an investigation system which identifies not only the immediate causes but also any underlying failures which led to the event. It should pay particular attention to cases of failures of protective measures (including operational and management failures), and should include investigation, analysis and follow-up, including giving information to personnel involved to ensure that the lessons learned are applied in future operation.”

IHF SaaS HF-AIR™ Solution: Comprehensive and Focused Incident Investigation Software Designed Using Best Practices from Human Factors Experts

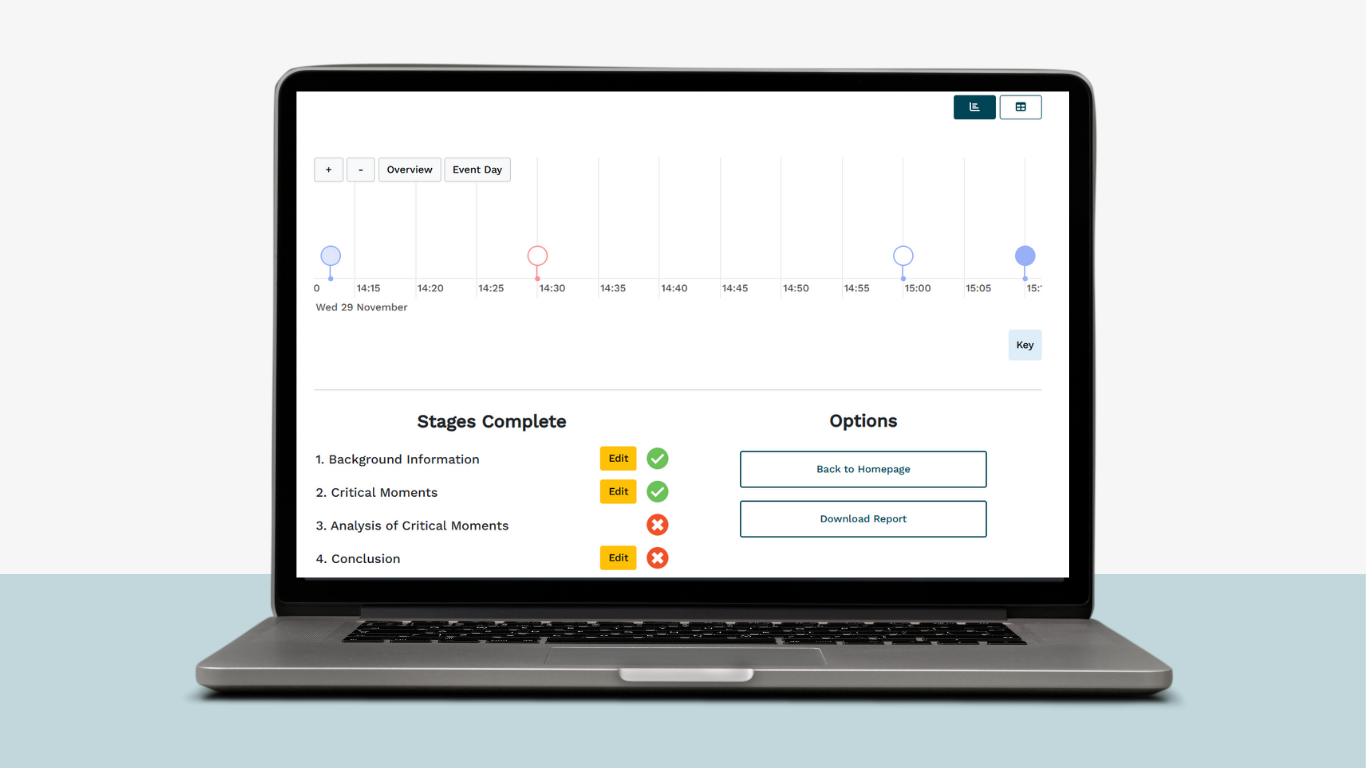

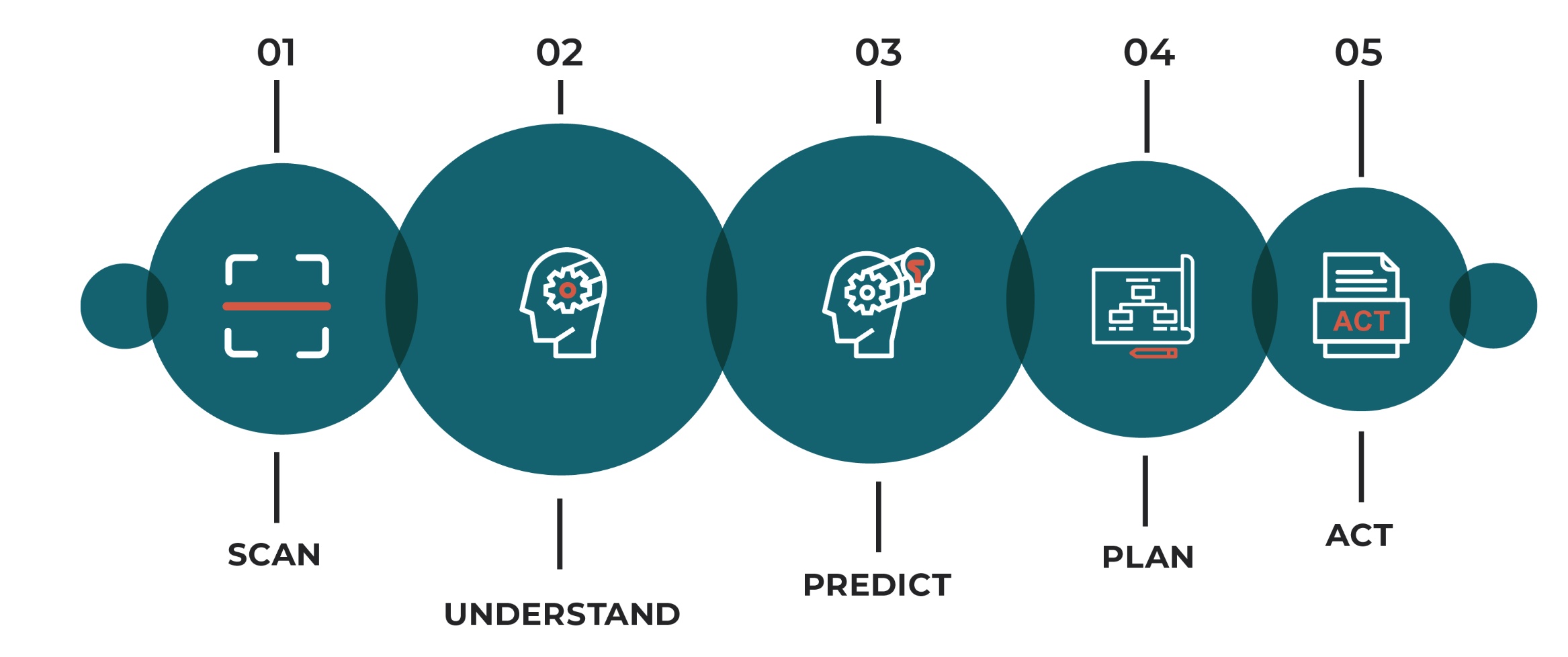

IHF SaaS HF-AIR (Human Factors Analyse : Investigate : Report) is a centralised digital incident investigation solution that enables organisations to go beyond surface-level human error identification and root cause box ticking. It is designed to investigate accidents and incidents thoroughly while meeting regulatory compliance by human factors experts. IHF SaaS HF-AIR uses the SUPPA™ (Scan – Understand – Predict – Plan – Act) investigative model that is based on situation awareness research to facilitate the integration of human factors into incident investigation. As a result, organisations can identify and learn from trends leading to proactive steps and targeted investment to reduce costs and mitigate accidents.

Centralise and Digitalise Your Accident and Incident Investigation Practice

IHF SaaS HF-AIR enables an auditable, centralised, repeatable and visible accident and incident investigation process. It is accessed through a web browser, eliminating disparate, duplicated and scattered documents, permitting a repository of accident and incident investigation collateral. This allows for a complete, consistent and controlled accident and incident investigation practice that can be efficiently reported to regulators with your company branded templates.

Visualise the Full Accident and Incident Investigation Process

IHF SaaS HF-AIR can enable enterprise-wide visibility of the full accident and investigation process using visualisation tools such as dashboards. These can be organised by human factors topic and a timeline featuring behavioural and non-behavioural causes such as machinery, methods, materials, mother nature and measurement causes with recommendations that can be specifically tailored to your organisation.

Meet COMAH-Critical Tasks Compliance

IHF SaaS HF-AIR is designed by human factors experts with comprehensive accident and incident investigation experience in line with recommend guidelines. IHF SaaS HF-AIR enhances and standardises the management of accident and incident investigation that are an integral part of regulations such as the general duty under COMAH and The Control of Major Accident Hazards Regulations 2015, Section 5.

SUPPA™ (Scan – Understand – Predict – Plan – Act) Investigative Model

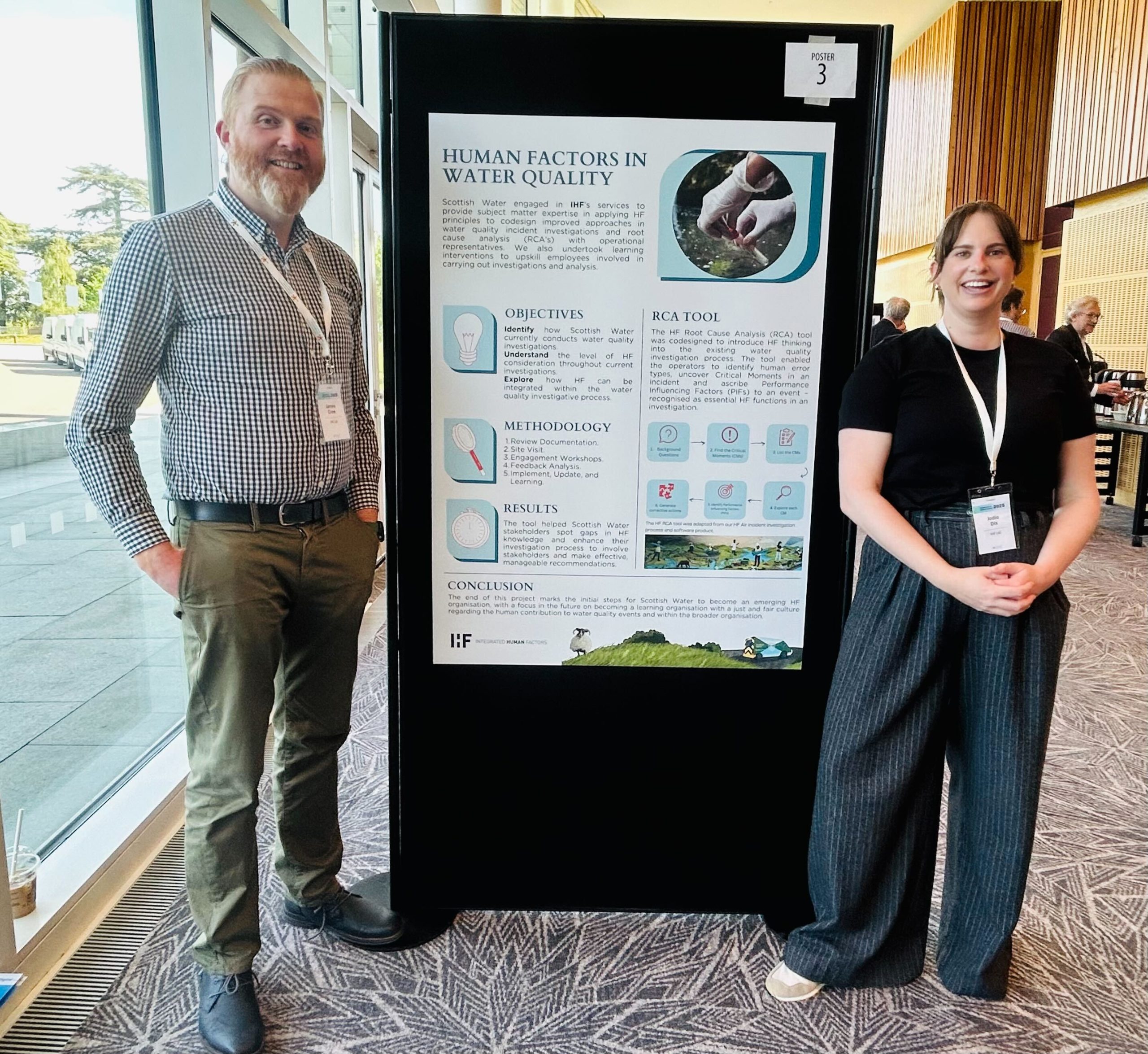

This figure illustrates the incident investigation process that IHF follows and advocates and is at the centre of IHF SaaS HF-AIR. The SUPPA™ (Scan – Understand – Predict – Plan – Act) investigative model is based on situation awareness research to facilitate the integration of human factors into incident investigation. Situational awareness describes a dynamic process where an individual takes in information from the outside world (Scan), makes sense of it (Understand) and then uses this information — in combination with their own knowledge — to Predict and Plan for what will happen next (Act). The process is dynamic as the individual’s awareness and knowledge of the situation and environment — their "mental model" — is being continually updated.

The Benefits of IHF SaaS HF-AIR to You, Your Workers, Your Organisation and the Public

Protect Humans and the Environment From Harm

Effective accident and incident investigation management can help mitigate repeated risks that may lead to tragic fatalities, injuries and environmental damage that emotionally, mentally and physically affect workers and the public.

Save Months of Investigative Time

IHF SaaS HF-AIR has allowed a client to conduct an incident investigation in a few weeks compared to the nine months it took to complete a single investigation. Time savings like this can help an organisation develop and maintain a positive relationship with regulators.

Save Weeks of Lost Incident Investigation Progress

Using paper, spreadsheet and word documents can lead to a lack of structure and may lead to missing steps or losing data in the accident and incident investigation process. Loss of or incorrect data is hazardous and can lead to weeks of rectification work.

Weeks Saved in Crucial Incident Investigation Reporting

IHF SaaS HF-AIR automates many steps of the accident and incident investigation reporting process including creating consistent reports in branded templates. This is more efficient and can lead to up to 3x report generation savings (reduced from six to eight weeks down to one or two weeks).

Single Version of the Truth

IHF SaaS HF-AIR standardises the accident and incident investigation by digitalising the process. The digital records enable dashboard visibility and timeline views that saves time searching for relevant information using traditional methods.

Leverage Award-Winning Human Factors Expertise

By investing in IHF SaaS HF-AIR you are also partnering with human factors experts who have a continuous improvement mindset and a passion to optimise workplace safety, demonstrated by the recent achievement of winning the Innovation Award at the Chartered Institute of Ergonomics and Human Factors (CIEHF) Awards 2024.

Multiple Safety-Critical Organisations Are Utilising IHF SaaS HF-AIR

"I was very impressed with the depth of knowledge that Neil and his team have about all aspects of human factors and Control of Work (CoW). They understand how these complex systems interact, are complied with and are used. IHF are, in my opinion, experts in all aspects of their field including training, consultancy and software implementation. I would not hesitate in recommending them to any organisation undertaking an investigation or CoW analysis."